Promotional operation "CLEARANCE"

Safety Shoes - Revision of the EN 20345 standards

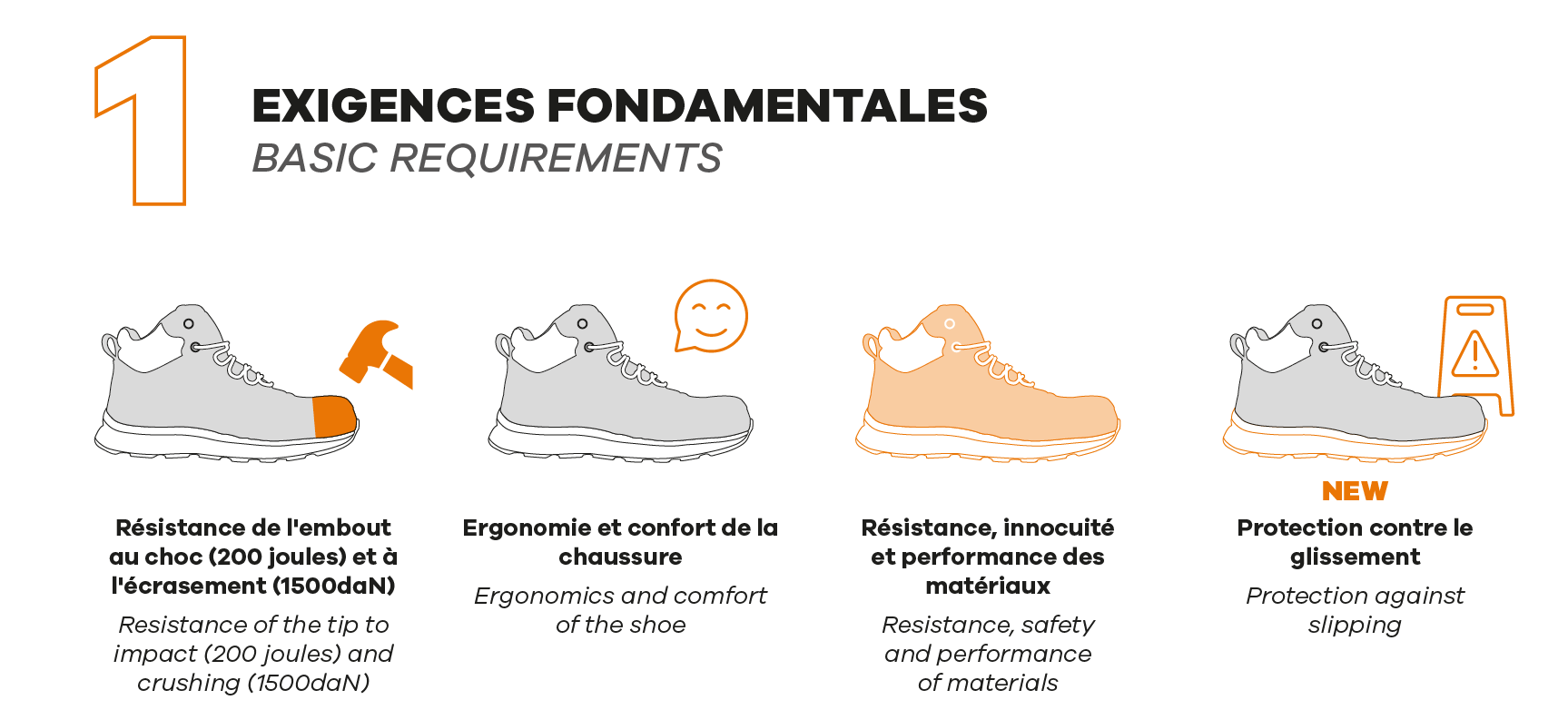

Revised in 2022, the EN 20345 standard for safety footwear has been revised to bring more simplicity and additional safety guarantees to professionals. Over a period of 5 years, all footwear then certified to EN ISO 20345: 2012 will have to migrate to the new EN ISO 20345: 2022 standard.

Manufacturers such as Coverguard can still rely on the old standard throughout 2022, but the transition will have to be completed within the next 5 years.

[TO SUM UP] What changes with the new standard EN 20345: 2022?

- Simplification of the slip resistance, disappearance of the SRA, SRB and SRC markings and new SR marking.

- The new perforation markings, evolution of the test with new names PL or PS according to the diameter of the tip used for the test

- The new S6 and S7 markings, they guarantee a better waterproofness of the shoes.

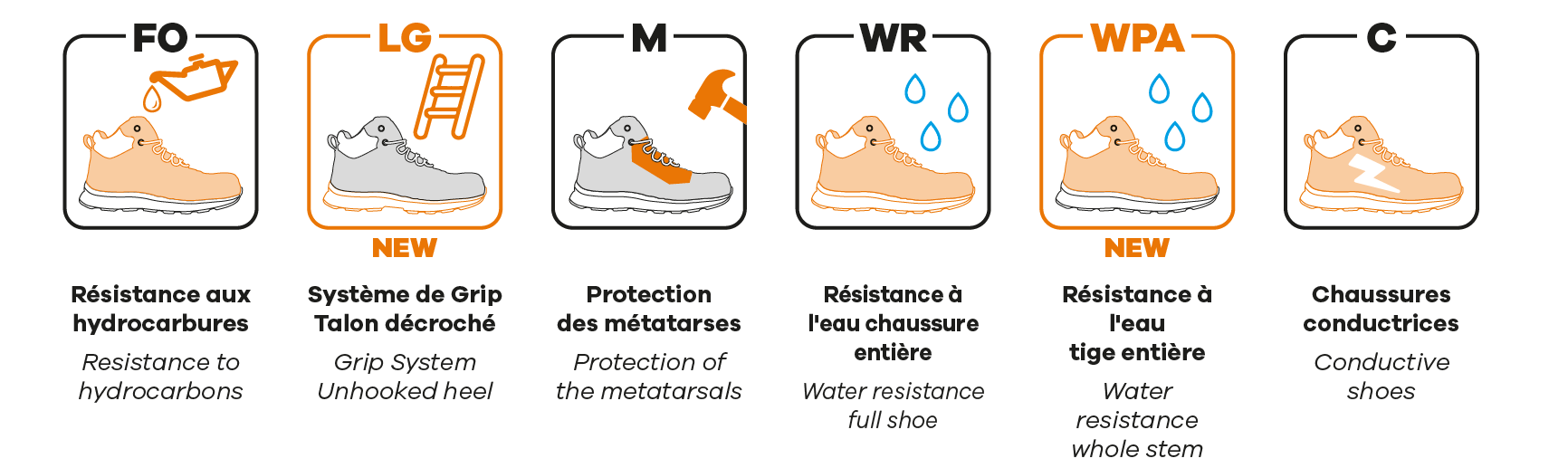

- The FO marking becomes optional for hydrocarbon resistance (FO)

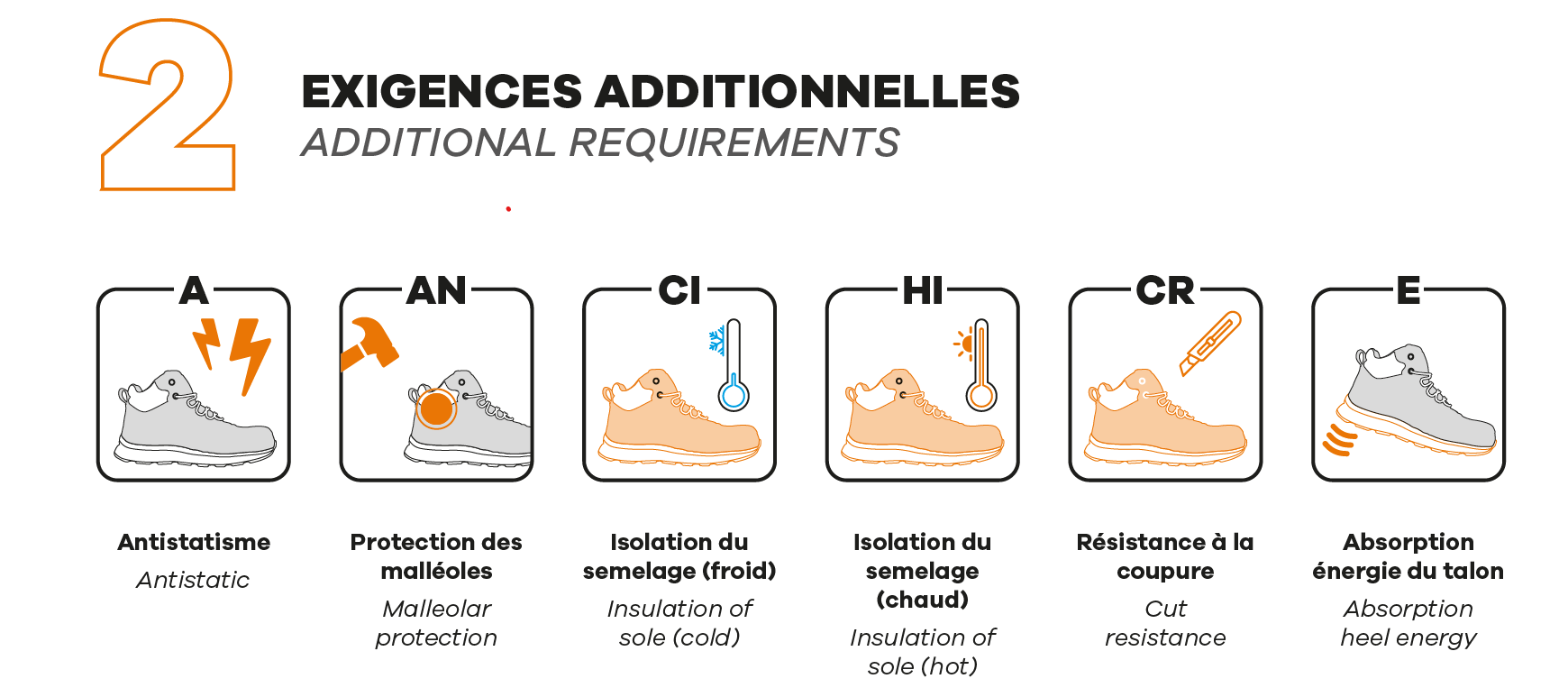

- New optional markings for toe caps (SG), unhooked heels (LG) and malleolar protection (AN)

SIMPLIFICATION OF SLIP RESISTANCE

With the new standard, the 3 markings SRA, SRB and SRC, integrated in the fundamental requirements (SB) disapear.

So in few words :

- SRA - Slip resistance on ceramic surface with water and soap (Sodium Lauryl Sulfate - NaLS)

- SRB - Slip resistance on metal surface with Glycerol lubricant

- SRC - Only valid if SRA and SRB tests are validated

From now on, in order to meet the basic requirements (SB), the test corresponding to the SRA level (slip resistance on ceramic surface with water and soap - Sodium Lauryl Sulfate - NaLS) becomes mandatory.The SRB marking disappears in favor of a new SR marking which is part of the additional requirements.

The difference between the two :

- BEFORE > SRB - Slip resistance on metal surface with Glycerol lubricant.

- NOW > SR - Slip resistance on ceramic floor with Glycerol lubricant.

Slip tests will now be performed on the heel and forefoot (vs. on the heel and flat of the sole currently).

Glide tests on cold surfaces (snow and ice) are under development. We will have to wait for a European reference.

THE NEW ANTI-PERFORATION MARKINGS

The (P) marking required until now for the S1P and S3 normative marking concerned all inserts: metallic, composite textile.

The (P) marking is retained, but now only for metallic anti-perforation inserts.

Non-metallic inserts (composite textile) are now divided into a (PL) marking: test performed with a "Large Point" of 4.5 mm diameter and a PS marking: test performed with a "Small Point" of 3 mm diameter.

- SIPS - S3S : marking (PS) ("small") : Anti-perforation of composite textile inserts for tests performed with a 3 mm fine tip

- SIPL - S3L Marking (PL) ("large"): Anti-perforation of composite textile inserts for tests performed with a 4.5 mm wide tip

NB : the PS type is not better than the PL type. The choice must be made according to the risk.

NEW S6 AND S7 MARKINGS

Two new markings, S6 and S7, have been introduced to distinguish between resistance to water penetration on the entire shoe (WR) or only on the upper (WPA).

Note: the additional requirement that was called WRU is now called WPA.

The S6 marking corresponds to the current S2 + WR marking

The S7 marking corresponds to the current S3 + WR marking

Also note: For the WR test, the requirements are becoming more stringent. Currently, the water passage should not be greater than 3cm². With the evolution of the standard, no water penetration must be observed.

THE FO MARKING BECOMES OPTIONAL

The FO marking attests to the resistance of a shoe to hydrocarbons.

Before, it was mandatory for S1 standard.

It becomes optional for all safety shoes S1, S2, S3, etc.

However, it is important to be careful: if the professional has to work in an environment where hydrocarbons are present, he/she must make sure that the shoe has been certified FO.

DES NOUVEAUX MARQUAGES OPTIONNELS ENTRENT EN PISTE

SC (SCUFF CAP = Stone guard)

This new marking concerns the over-tips of protections (also called "stone guards"). It is intended to attest their real efficiency and allows to distinguish the thin over-tips which are just aesthetic from those which have a real functional use.

These inserts will now have to resist the abrasion resistance threshold defined by the standard (Martindale test). The reinforcement must not show any hole on its entire thickness before 8000 cycles (test performed with 180 grit sandpaper - pressure 9kPa)

LG (LADER GRIP)

This new marking defines the requirements for unhooked heels. They must reach a certain size to be LG standard.

The material of the camber must also meet the abrasion resistance requirement. The lugs in the arch must be transverse and the sole must meet the "lugged sole" requirements.

AN (ANKLE PROTECTION)

The dimensions of the ankle protection inserts are now defined.

SHOES SIZES MINIMUM DIAMETER IN MM

≤ 40 55

41 à 43 60

≥ 44 65

[WHAT CHANGES FOR COVERGUARD?]

All new Coverugard safety shoes arriving between late 2023 and early 2024 will be certified to the new EN 20345:2022 standard.

For existing models, the change will occur as certificates are renewed, starting in April 2023 (for the first models whose certificates expire).